Demineralization ( DM ) Water Treatment Plants

We are Manufacturer, Supplier, Exporter of Demineralization ( DM ) Water Treatment Plants and Our setup is situated in Pune, Maharashtra, India.

Demineralization (DM) is the process of removing minerals, salts ( such as cations - sodium, calcium, iron, copper, and anions such as chloride, sulphate, nitrate, etc) from Water by using one of the following processes :

- Ion Exchange ( Cation- Anion- Mixed Bed) Treatment

- Membrane Filtration (Like Reverse Osmosis followed by MB )

- Electro DeIonisation (EDI)- RO+ EDI

- Distillation / Evaporation

Ion Exchange: Demineralised (DM) Water known for typical conductivity < 30 umhos/cm. Deionised (DI) Water is known as more purified DM water with the help of a Mixed Bed (MB )unit or Electro De-Ionisation (EDI). MB-based DI water produces Conductivity < 5 umhos/cm. EDI-based DI water produces Conductivity < 0.5 umhos/cm.

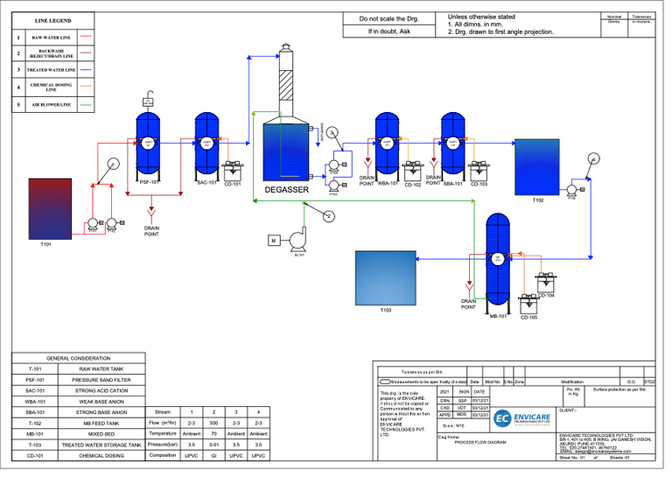

Raw Water Pretreatment

Most of the time its desired that raw water be treated for the removal of the suspended solids (TSS) with the help of a Pressure Sand Filter (PSF) and to be treated for removal of Colour, Odour and Organic matter with the help of Activated Charcoal Filter (ACF). These units shall help in enhancing the life of the resins/ membrane and to offer the desired water quality.

The membrane-based systems like RO+MB is becoming more popular because of automation in the membrane system and less manpower requirement for the regeneration process.

Distillation is nowadays outdated technology due to electrical power consumption.

Evaporation such as MEE is being used in the recycling of wastewater.

Principles

Majorly 2 principles were used for producing DM/DI quality water:

- Ion Exchange adsorption - The cations and anions present in water are replaced with the active resin parts and then recharged by using acid and alkali.

- Membrane separation - Reverse Osmosis followed by MB - The Total dissolved solids get separated with a semipermeable membrane leaving behind very low salt at permeate (product) side.

Envicare's DM Water Plant's Advantages:

- Variety of cost effective standard Manual & Auto models.

- Improved aesthetics and rugged design.

- User friendly, low maintenance and easy to install.

- Simpler distribution and collection systems.

- Quick availability.

- Pre dispatch assembly check.

- The multiport valves are top mounted as well as side mounted with the necessary high pressure rating PVC piping.

- Single valve operation as compared to the six valves in conventional filters

- Each operating step is clearly marked on the valve, thereby eliminating chances of error in the operating sequence.

- Single valve assembly, with its simplified frontal Piping, simpler distribution collecting systems is Very easy to install.

- Rust free

- Less power consumption

- Durable

- Economical

- High shelf life

Major Applications

Boilers feed Water, Textiles, Pharmaceuticals, Chemicals, Breweries, Cooling Towers Potable Water, Hospitals, automobiles, and Battery, and Fertilisers

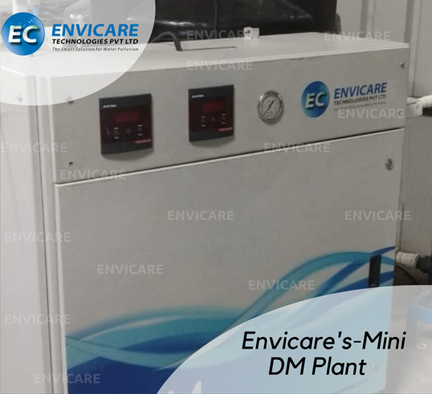

Portable or Mini- DM Water Treatment Plant

The Water free from any mineral is called De-Mineralised Water (D.M.Water). Naturally occurring Water has various salts in dilute form which are called dissolved solids (TDS). When the Water having such mineral is required to be free from this, it is to be treated in Ion Exchange Resins column (H form) which adsorbs the positively charge ion. Now the cations free passed through Anion Resin Column (OH form) which adsorbs the negatively charged anions and Water free from the total ions shall comes out from the system.

| 1 | Type | Mini DM Plant – Cabinet and Open Skid Type |

| 2 | Technology | Resin Based DM Plant |

| 3 | Model | eDM - 05 |

| 4 | Flowrate | Between 50 & 80 LPH |

| 5 | OBR (Output Between One Regeneration) | ~ 400 Lit @ 100 ppm Input water TDS ( best suitable for corporation feed water) |

| 6 | Output TDS | < 10 ppm |

| 7 | For better water quality < 1 ppm Output TDS | MB (Non Regenerative) – 05 Can be added |

| 8 | Size | Compact - Approx. 1.0 x 1.0 x 1.0 M |

- Model : eDM-5

- Flow rate : 50 to 80 Lit / hr.

- Space requirement : very compact- 1 m x 1m

- Power : NIL, Min inlet pressure 0.5 kg/cm2

- Output TDS : Less that 10 ppm

- Output DM Qty. : 500 Lit at 100 ppm (Best suitable when feed Water is corporation Water TDS < 100 ppm)

Applications

Food Industry, Pharmaceutical industry, Automobile, laboratory, and many more.

| SR # | Description | Your Comments |

| 1 | Source of Water- Corporation/Lake/Well/Bore-well ? | |

| 2 | Usage Of DM Water- Any specific purpose ? Answer Why you required the DM water? What problem are you facing currently and want to solve? | |

| 3 | Total quantity of Water required per day basis (This is required to set the OBR) ? | |

| 4 | Inlet Water Parameters like - pH, TDS, Hardness, Chlorides, Turbidity, TSS in mg/lit ? ( Pls attach the report, If any) | |

| 5 | Usage Of DM Water- Any specific purpose ? Answer Why you required the DM water? | |

| 6 | Output water Quality in Terms Of TDS / Conductivity in mg/lit ? | |

| 7 | Any specific Technology looking for ? | |

| 8 | Any specific Budget allocated? This will help us to select the specific technology, brand while designing the system |

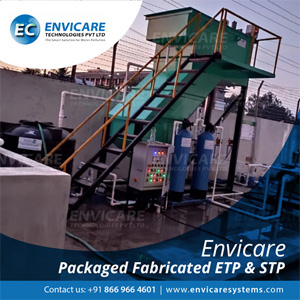

- Effluent Treatment Plants ( ETP )

- Sewage Treatment Plants ( STP )

- Bag Filtration Systems

- Filter Presses

- Demineralised ( DM ) Water Treatment Plant

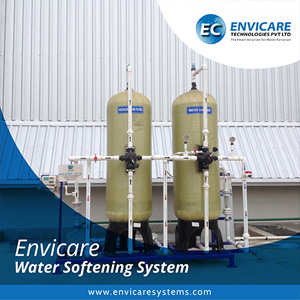

- Automatic Water Softener

- Oil Skimmers

- Reverse Osmosis ( RO ) Water Treatment Plant

- Water Purifiers

- Water Treatment Plants ( WTP )

- Rain Water Harvesting ( RWH )

- STP, ETP, WTP, WWTP AMC ( Annual Maintenance Contract ) Services

- Pollution Control Board ( PCB ) Compliances

- R&D Laboratory

- E-Microbes For Problematic STP and ETP New